|

|

Now

is the moment of truth. Clamp your pins in a vise and tap down the

tails with a mallet. I always use a piece of scrap to make sure I

tap evenly and protect the work from dents. If your layout and sawing

was accurate, the pieces should just tap together. But don't force

it. If the parts get stuck, take them apart and pare away any interference.

Be careful of the visible edges. If you have a gap, don't worry too

much about it. You can always fill it with veneer (be sure to match

the grain direction). Watch for small splits occuring usually at the

edge of a joint, especially at the ends of the tails. This happens

if the joint is too tight. |

|

|

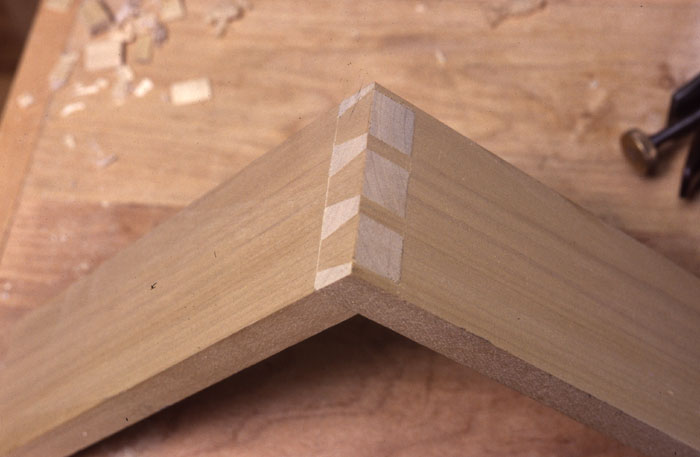

In

this particular case, one of the tails was a little tight and a split

started. Paring along edge of the tail took off just enough so that

the wood came together properly. Sometimes you can tell by the sound

of the joint when you tap on it if it's too tight or loose. Wear marks

on the joint when you take it apart are another giveaway. You can

see in this picture there are little bits of wood in the corners of

the pins that must yet be pared away before the joint can be malleted

closed. |

|

|

Glue-up:

Finally,

glue up the joint and let it dry. When you glue up, remember that

the joints are cut slightly deeper than the thickness of the wood

so you have to put pressure on the joint to press the pins below

the surface of the tails. The simplest way to do this is to take

a scrap of wood and cut it away where the pins are so that when

you clamp down, the pressure is all on the tails. When you clamp

the joint, check for squareness. It is easy to be see that the joint

is closed up and forget that the insides might be open. So check

that the tails are totally down in their sockets and that the work

is square before the glue sets up.

|

|

Planing

flush:

When

the joint is fully dry, the fastest and easiest way to finish it

is by planing the protruding pins and tails flush, or by using a

sander.

|

|

|

Finished!

|

|

|

|