|

|

01/04/2017 |

Happy New Year! I thought I would start off the new year with some practical woodworking information. I have always thought that a grinder is one of the most important tools in the shop -- and it's also one of the least understood. While I do teach an occasional class on grinding at our shop (and will do so again in the future), most people don't live nearby, so written instruction seems in order. The last time I wrote on this subject, in the June 2008 issue of FWW, the response was overwhelming. But I have learned stuff since then, and technology has evolved.

This series on grinding is in six parts:

Part 1: Introduction + When To Grind.

Part 2: The Technology of Grinding, Grinders, and Grinding Wheels.

Part 3: Grinding Wheel Chemistry and Nomenclature.

Part 4: Dressing Your Grinding Wheel for Cool Running.

Part 5: Grinding the Hollow.

Part 6: Repairing a Damaged Edge Without Burning the Steel.

Parts three through six are hands-on; the rest is theory and background information.

There are three reasons to grind.

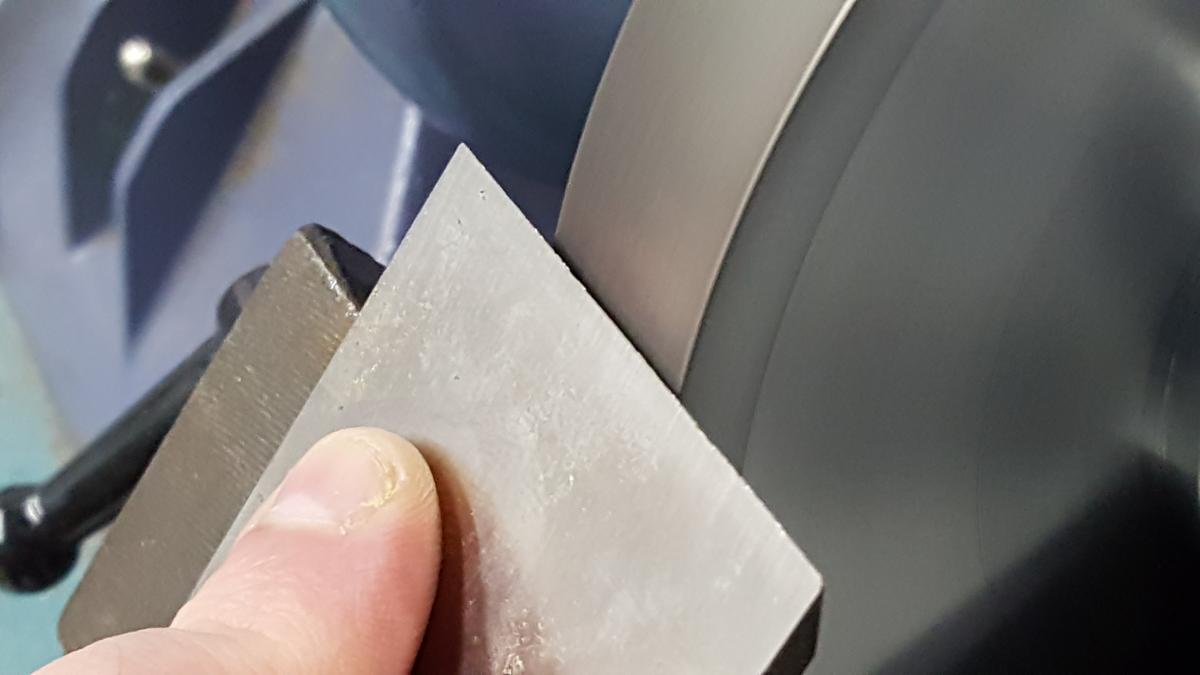

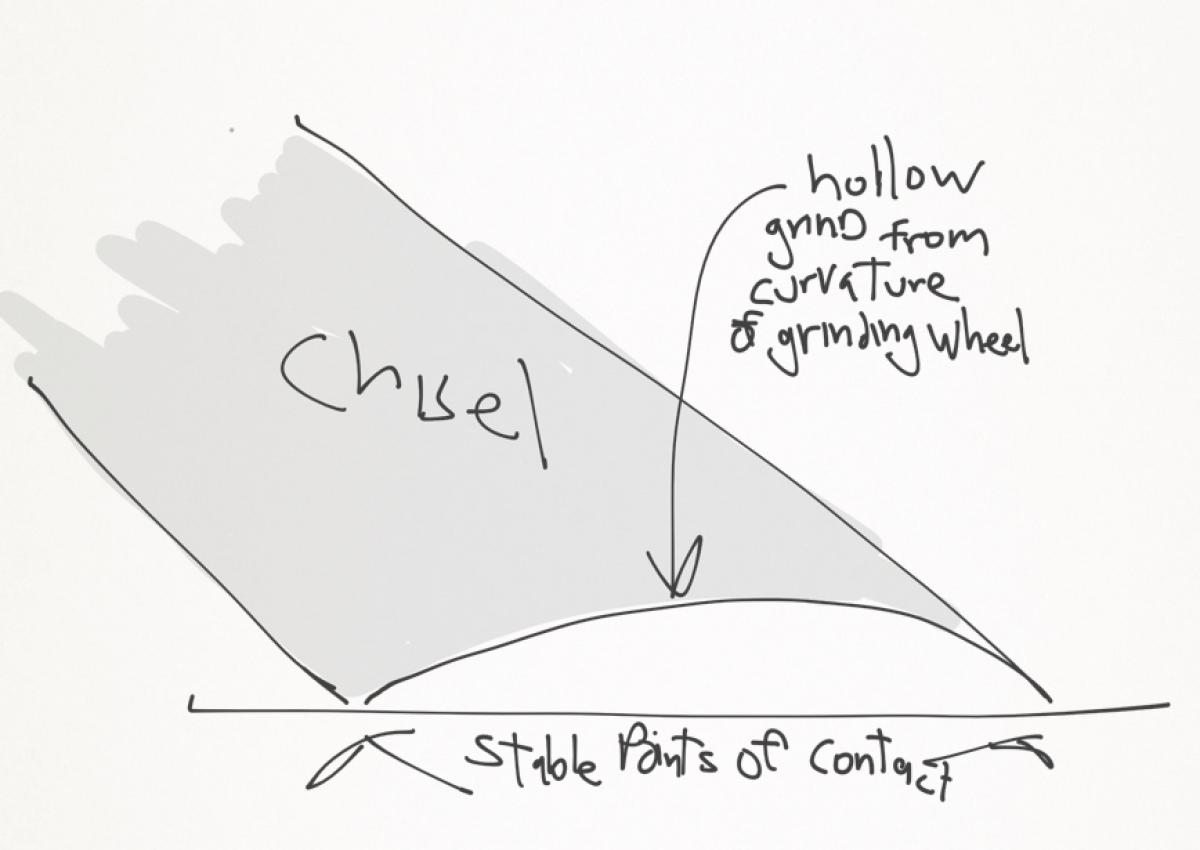

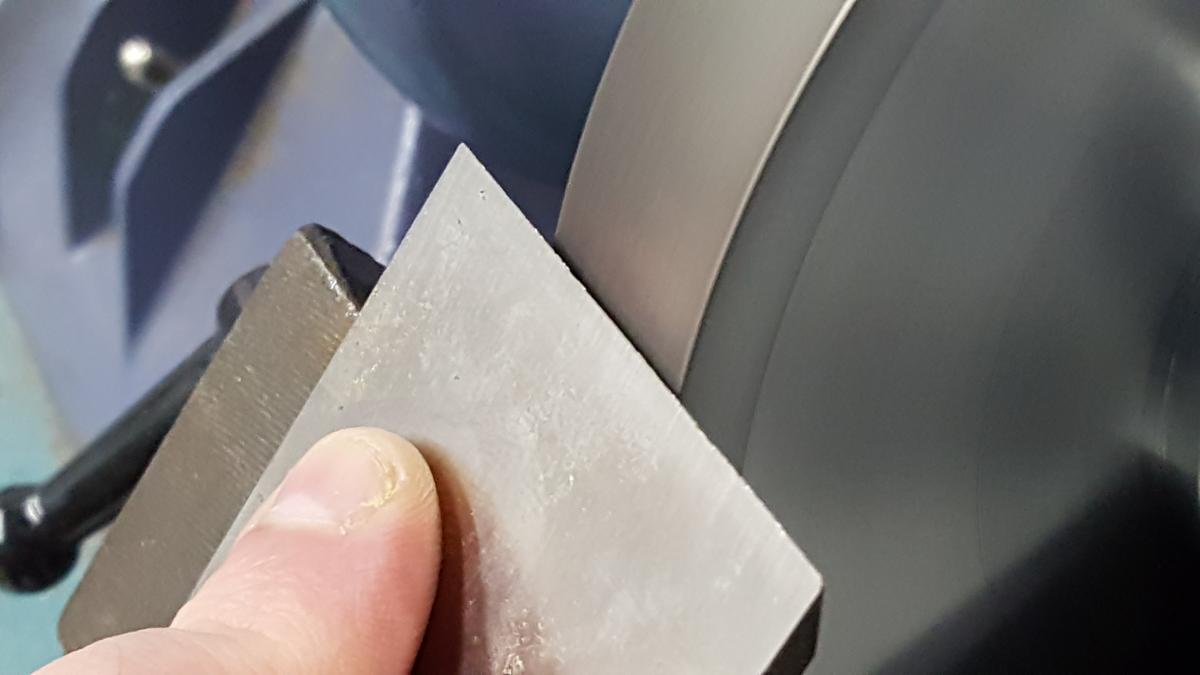

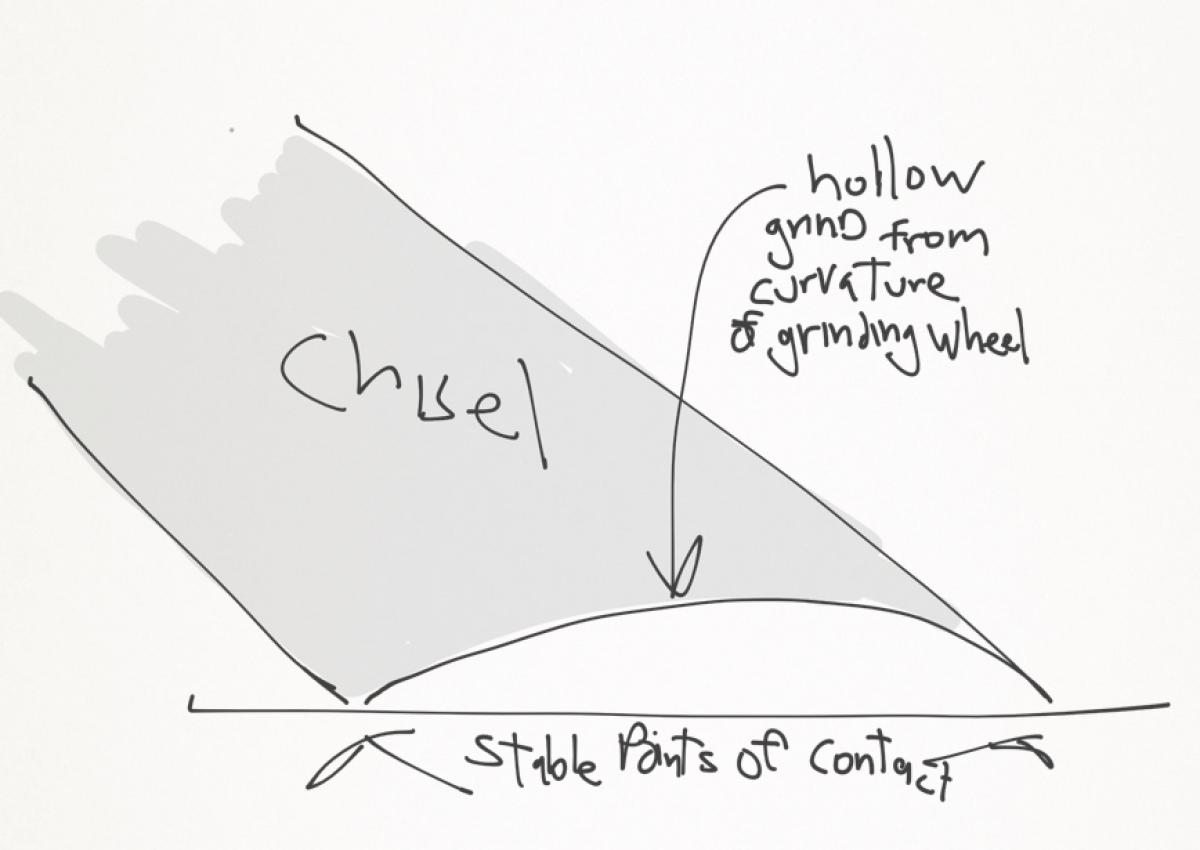

1 - To Maintain a Hollow Grind. Grinding an edge tool against a curved wheel will always result is some sort of curvature on the bevel. The larger the wheel, the less the curvature. We call this "hollow grinding" (see picture). Producing a hollow grind enables easier and faster honing. When you think about it a bit, the only part of the chisel that does any work is the cutting edge at the very tip. The rest of the chisel is just support for the edge. So the steel in the middle of the primary bevel is basically waste. With a hollow grind when you go off to hone the tool after grinding, you get a very stable platform of the tool solidly supported at the front and back edges of the bevel. You won't be wasting energy, stone wear, and time removing the middle of the bevel, you'll also get a simple way to make sure you are always honing at the edge. All the force is applied at the edge, and there is no tendency to wobble or rock the chisel. Hollow grinding GOOD! 1 - To Maintain a Hollow Grind. Grinding an edge tool against a curved wheel will always result is some sort of curvature on the bevel. The larger the wheel, the less the curvature. We call this "hollow grinding" (see picture). Producing a hollow grind enables easier and faster honing. When you think about it a bit, the only part of the chisel that does any work is the cutting edge at the very tip. The rest of the chisel is just support for the edge. So the steel in the middle of the primary bevel is basically waste. With a hollow grind when you go off to hone the tool after grinding, you get a very stable platform of the tool solidly supported at the front and back edges of the bevel. You won't be wasting energy, stone wear, and time removing the middle of the bevel, you'll also get a simple way to make sure you are always honing at the edge. All the force is applied at the edge, and there is no tendency to wobble or rock the chisel. Hollow grinding GOOD!

2 - To Restore or Change the Geometry of the Primary Bevel Angle. Personally I am not fussy about bevel angles. The lower the angle of the primary bevel, the less force it will take to push the chisel into the wood. With less force comes more control. The trade-off is a thinner, weaker edge. A higher primary angle gives you a stronger edge, but more force is needed to punch it into the wood, and with that comes less control. The traditional angle of a bench chisel is 25° but a little more or less isn't a big deal. Paring chisels should really be lower by at least 5° and mortise chisel higher by the same amount. Every once in awhile I realize that my geometry on a particular chisel or plane blade is off enough to annoy me. This usually happens because after several years of honing I find the bevel angle getting steeper. These days, however, as I am hollow grinding to make honing easier and I don't have this problem at all. I'm also not personally adding new chisels to my toolbox - but certainly someone building a shop will always have "new to them" tools that need a geometry change.

3 - The Unfortunate Reason: To Restore a Damaged Edge. Probably the most frequent reason I end up grinding something. Chisels, plane irons and other display tools in our showroom get handled all the time and get dropped. Repairing a damaged edge is a little more involved than a just maintaining the hollow, but there really is no better way of repairing a damaged edge. Honing past damage, even with a coarse abrasive, just takes a lot of time and elbow grease.

The issue that many woodworkers are scared about when grinding is heat. The basic problem is that (with the exception of turning tools made from High Speed Steel (HSS)) if you heat up a hardened piece of steel past 400 degrees it will get start turning brown and blue and get softer -- and most importantly, it won't keep an edge anymore. HSS is called "High Speed Steel" because it can be heated up way past 400 degrees and yet stiff hold an edge. But in general, HSS won't hold a sharp enough edge for woodworking, and it's very hard to hone. The goal when grinding an edge is to achieve a ground edge without overheating or "burning" the edge. And a more important goal is to be able to consistently grind without burning because otherwise the crap shoot of what will happen is too scary.

There are three (or four) basic approaches to keeping cool when grinding. Use a very slow grinder. Use a grinding wheel that allows speedy steel removal without heat. Use some sort of coolant, such as water for wet grinding. Finally in parentheses: (grind really slowly and gingerly). The goal for me is to grind as fast as possible without any real danger so in Part Two we will talk about wheel and grinder selection, and how to keep a wheel grinding as cool as possible.

|

Join the conversation |

|

Joel's Blog

Joel's Blog Built-It Blog

Built-It Blog Video Roundup

Video Roundup Classes & Events

Classes & Events Work Magazine

Work Magazine

1 - To Maintain a Hollow Grind. Grinding an edge tool against a curved wheel will always result is some sort of curvature on the bevel. The larger the wheel, the less the curvature. We call this "hollow grinding" (see picture). Producing a hollow grind enables easier and faster honing. When you think about it a bit, the only part of the chisel that does any work is the cutting edge at the very tip. The rest of the chisel is just support for the edge. So the steel in the middle of the primary bevel is basically waste. With a hollow grind when you go off to hone the tool after grinding, you get a very stable platform of the tool solidly supported at the front and back edges of the bevel. You won't be wasting energy, stone wear, and time removing the middle of the bevel, you'll also get a simple way to make sure you are always honing at the edge. All the force is applied at the edge, and there is no tendency to wobble or rock the chisel. Hollow grinding GOOD!

1 - To Maintain a Hollow Grind. Grinding an edge tool against a curved wheel will always result is some sort of curvature on the bevel. The larger the wheel, the less the curvature. We call this "hollow grinding" (see picture). Producing a hollow grind enables easier and faster honing. When you think about it a bit, the only part of the chisel that does any work is the cutting edge at the very tip. The rest of the chisel is just support for the edge. So the steel in the middle of the primary bevel is basically waste. With a hollow grind when you go off to hone the tool after grinding, you get a very stable platform of the tool solidly supported at the front and back edges of the bevel. You won't be wasting energy, stone wear, and time removing the middle of the bevel, you'll also get a simple way to make sure you are always honing at the edge. All the force is applied at the edge, and there is no tendency to wobble or rock the chisel. Hollow grinding GOOD!

Look forward to more. Thanks a lot.

I have used it, and my arm heats up 'way before the metal does. Funny, that didn't happen when I was 8 years old, cranking it for my grandfather. So far now, I have only salvaged the shape of some of his old screwdrivers.

As I say in my article - I'm not that fussy. Bevel down plane blades are ground at approximately 25 degrees. Bevel up ones should be ground at whatever operating angle you wish.

Kevmeister68,

If the side to side wobble is a tilt there might be a problem with your flanges. If the side to side is the entire wheel shifting your problem is play in the shaft. If course you might have some other issue, but those are the most common assuming the wheel bore is correct and true.

William.

Grinding is the process of removing metal using a moving abrasive and a stationary edge. It is usually an operation where the wheel is powered, but foot and hand cranked grinders were also common. It is used for gross metal removal.

Honing is the process of manually moving the edge tool back and forth over an abrasive. This much slower but also much easier to control. There are also such things as power hones - which are basically very fine grinding wheels. Honing is used for creating the final edge and polishing it up.

Stropping is the process of moving, usually by hand an edge back and forth over either plain leather leather (or paper or wood) charged with a find abrasive. These media are far more forgiving than a hard stone and are especially useful in doing the final work on carving tools and cleaning off the last bit of wire edge on a honed tool. Power stropping using a charged paper or leather wheel is very common.

Jeff,

A living history museum might want your hand cranked grinder, but also someone in a local woodworking club might want it too. A school (see your local Steiner School) might welcome a grinder that kids can use very safely.

Demand comes and goes, but that hand cranked grinder is quite valuable to some. I am more of a kanaban user myself, but one of the things I like to do is from scratch woodworking during power outages. In times like that, a hand crank grinder is a pretty sweet item to have around. If you want to grind slowly and not hurt the temper, a hand crank grinder is once again, a very nice thing to have.

Unless of course you use a kanaban. :)

I have a very large foot powered and recently (30's) motorized wheel.

Donating it to a school is a very good idea.