|

|

09/06/2008 |

When it comes to woodworking I get asked at least once a day what sharpening stones I use. When it comes to woodworking I get asked at least once a day what sharpening stones I use.

The truthful answer is - whatever is closest. And I'm not kidding. basically just about any sharpening media works within the parameters of what it's good for so when I need to put on a quick edge on something of regular steel the closest set of stones I have is what we use.

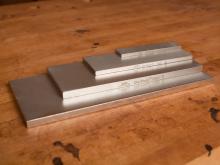

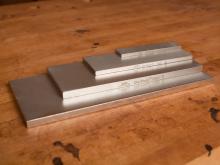

That usually translates into the Naniwa Superstones(update: No longer available we have switched to Pride stones or Diamonds ) which not only are on display in the showroom which is outside my office on the way to my workbench, they also don't need to be soaked so I can use them instantly and they are soft enough so flattening them doesn't require much time or effort. So that's why I use in the shop and I'm pretty happy.

The exception is when I need to sharpen carving tools and then I have to find out who has the Multi-Stone(update: no longer available). The multi-stone has a tendency to wander from the showroom into the manufacturing workshop and that means a 200 foot walk back and forth when it isn't in the showroom as it's supposed to be. The reason is that the folks in the manufacturing workshop are always polishing this or that and they need precise stones that don't groove or round easily. And the guys there end up using and really liking oilstones for everything because - well they just do.

I come home every night and cook dinner so I do a lot of slicing and trimming and my kitchen knives need to get sharpened occasionally. I typically sharpen all the working knives in the kitchen at the same time. When we first got in the Superstones Naniwa also sent a set of Choseras stones which they consider their top of the line and what's preferred by top knife sharpeners and sword polishers (the ones who don't use/can't afford natural stones).

I "tested" them out and was sold instantly because the lower grits were cutting faster than anything else I had and the 10K is flat out the finest finishing stone of any grit of any brand I have ever seen - even some of the so-called very high grit stones. The whole series (like most Naniwas stones) is designed for people who like a natural feel and the 10K on top of that leaves a polish that is incredible. I think it has to do with the consistency of grain, followed by the way the slurry breaks down like a natural stone. It's just wonderful.

But there is always a but. The whole line is really expensive and I didn't think most woodworkers would find the incremental benefit of the stones worth the extra coin. So we didn't import them and the samples ended up in my kitchen where every time I sharpened I just smiled quietly to myself.

A year goes by and Super Stones are selling like crazy and I start getting requests from knife people about these Chosera stones. And when I mentioned the price folks seemed to think it was worth it, considering what a top notch quality natural stone costs.

So we brought in a bunch. I can't recommend them on a "Value" basis - but they are like an Lamborghini - and I can strongly recommend them on a "Performance/Pleasure" basis. So if you are looking for the finest waterstones available on the planet today - this is the line you should consider - especially the 10k Stone.

ps - I have started to use them on D2 and some of the other even tougher alloys I use and I am really pleased at how fast the stone cuts. Certainly faster than anything else I own.

|

Join the conversation |

|

Joel's Blog

Joel's Blog Built-It Blog

Built-It Blog Video Roundup

Video Roundup Classes & Events

Classes & Events Work Magazine

Work Magazine

thank

rocco savino ill wait to hear from you

Only if you can tell me what your current schedule of sharpening stones is missing. That is if you are getting the edge you like now there is no need to up grade, although the Chosera's will sharpen faster - which might be an advantage to you and worth the extra cost.

In any case you are welcome to come to the store, bring a razor and try them out. - just let us know beforehand when you are coming.