|

|

03/17/2008 Fast and Fun!! |

I own pretty much almost every type of sharpening stone out there. Some I have because I actually use them in a regular way, some I have because I needed to evaluate the stones for possible sale, and some, of course, because we stock a pretty big range of stones. I own pretty much almost every type of sharpening stone out there. Some I have because I actually use them in a regular way, some I have because I needed to evaluate the stones for possible sale, and some, of course, because we stock a pretty big range of stones.

At work I seem to be using our new Superstones (update: not currently available) more and more, primarily because they don't need to be soaked and consequently don't require any waiting around before use. Popular Woodworking just gave us a nice review and I think Chris's comments are pretty on the money.

The "not soaking" part is very convenient. It takes away the planning stage of sharpening. Also, soft stones don't glaze and cut pretty consistently. In general I just love the feel of the stone. That's one of the features that Naniwa is very proud of. Because the stones are so soft, they flatten very quickly. They also work well on A2 and D2, which is important.

I also use my Norton stones a lot, but I think the Norton is like a Cadillac - solid, powerful, reliable, consistent. The Superstones are like a Ferrari, fast and fun.

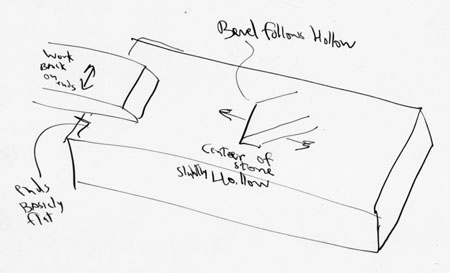

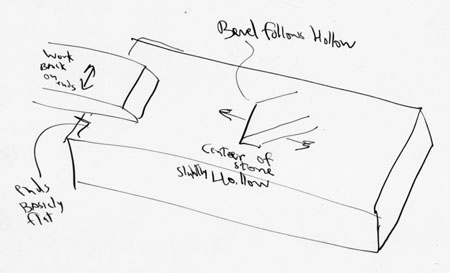

One tip you may find useful: flat stones are important, especially when you work the back and an iron. With typical use, waterstones go hollow in the middle. For a change of pace, I sometimes work the backs of irons by going on a short stoke from side to side along the ends of the stone (as opposed to going from end to end, as is usually done).  The ends of the stone normally get very little usage, so they are usually flat even if the stone itself is a little hollow. When I work the ends, it evens out the wear on the stone and I flatten less. There is that trade-off of the shorter stoke, but unless the back is really bad, it's not a big deal. And of course when I do the bevel, only a little bit of blade contacts the stone so even if the stone is a touch hollow it's not a big deal - as it follows the hollow. I am not advocating hollow stones; I'm simply saying that by evenly using the stones you can be a little less compulsive about flattening them constantly. The ends of the stone normally get very little usage, so they are usually flat even if the stone itself is a little hollow. When I work the ends, it evens out the wear on the stone and I flatten less. There is that trade-off of the shorter stoke, but unless the back is really bad, it's not a big deal. And of course when I do the bevel, only a little bit of blade contacts the stone so even if the stone is a touch hollow it's not a big deal - as it follows the hollow. I am not advocating hollow stones; I'm simply saying that by evenly using the stones you can be a little less compulsive about flattening them constantly.

Note: after I wrote this, I realized that if you sharpen free-hand, the normal pressure on the bevel will keep the edge in contact with the stone - even if the stone is hollow and you have several stones with different hollows. If you sharpen with a jig, that's not always the case. Different stones with different hollows may not contact at the edge you're sharpening (they won't, actually, if the finer stone has less hollow, which is usually the case). It's another reason to sharpen free-hand. But even if you don't sharpen free-hand, using the end of the stones for the backs will even out wear and reduce the number of flattenings you have to do.

BTW the photo shows me flattening a bunch of Superstones using sandpaper and glass. I normally use the Norton Flattening Plate (which I helped design and use all the time) to flatten all but the 12k and sometimes 8K stones, but that day the glass and sandpaper happened to be closer at hand.

|

Join the conversation |

|

Joel's Blog

Joel's Blog Built-It Blog

Built-It Blog Video Roundup

Video Roundup Classes & Events

Classes & Events Work Magazine

Work Magazine

I own pretty much almost every type of sharpening stone out there. Some I have because I actually use them in a regular way, some I have because I needed to evaluate the stones for possible sale, and some, of course, because we stock a pretty big range of stones.

I own pretty much almost every type of sharpening stone out there. Some I have because I actually use them in a regular way, some I have because I needed to evaluate the stones for possible sale, and some, of course, because we stock a pretty big range of stones.  The ends of the stone normally get very little usage, so they are usually flat even if the stone itself is a little hollow. When I work the ends, it evens out the wear on the stone and I flatten less. There is that trade-off of the shorter stoke, but unless the back is really bad, it's not a big deal. And of course when I do the bevel, only a little bit of blade contacts the stone so even if the stone is a touch hollow it's not a big deal - as it follows the hollow. I am not advocating hollow stones; I'm simply saying that by evenly using the stones you can be a little less compulsive about flattening them constantly.

The ends of the stone normally get very little usage, so they are usually flat even if the stone itself is a little hollow. When I work the ends, it evens out the wear on the stone and I flatten less. There is that trade-off of the shorter stoke, but unless the back is really bad, it's not a big deal. And of course when I do the bevel, only a little bit of blade contacts the stone so even if the stone is a touch hollow it's not a big deal - as it follows the hollow. I am not advocating hollow stones; I'm simply saying that by evenly using the stones you can be a little less compulsive about flattening them constantly.

This was a great insight into a relatively new series of stones, so does this mean that you have given up your oil stones? If not, how about you give your readers an insight on them? How many stones do you us and how much? What do you flatten them with? i thin it would generae some good old fashioned "discussion", so I hope that you feel the way I do, so plase think about it.

Thanks,

Michael

I love my oilstones. I have had them for over 25 years. As I have mentioned before I'm not dogmatic about sharpening media and a lot of times I use what's closest. The superstones not requiring soaking give the same immediacy as oilstones but of course the supestones are soft and require much more maintenance. For carving tools and any not straight tool I don't think you can beat an oilstone for low maintenance and for regular carbon steel oilstones also work great. However for A2, D2 and other tougher stuff oilstones don't work very fast or well so I need something else.

Garrett Hack advocates using .5 micron diamond paste on an Arkansas stone to speed it up, which works, Larry Williams advocates routinely flattening the Arkansas stone with a diamond stone to give it more bite so it cuts faster. That works, but if I have to do stuff like that I might as well go the waterstone route.

We do use Arkansas stones in the toolroom for stoning saws and other precise sharpening where a soft stone would ruin the geometry of what we are sharpening up.

We have ready for use in the shop here: A Norton Multistone, Superstones, and ready for soaking Norton stones. I like them all in different circumstances.

Just out of curiosity how often do you find that the norton flattening plate

needs to be flattened?

I have one that I rarely use but I think it works better than my DMT stone for

flattening. I just don't use it much because I wonder when I will need to

flatten it.

Oh, and do you take the stone to the flattening plate or the plate to the

stone? I've tried both and I'm curious about your thoughts.

Thanks

Peter

1) I don't use it on the 220 grit stone. That stone will wear the flattening plate.

2) soak everything before flattening. otherwise the flattening plate will clog.

3) if it does go out of flat i suppose you can flatten it on a sidewalk.

I usually hold the stone in one hand, the flattening flat in the other and rug together over the soaking tub. STart with the finer girt stones first to minimize contamination. Then wash everything.

another tip. If your stone is convex rubbing it with a flattening plate will maintain the convexity - no matter how flat and expensive your flattening plate is. The solution is to remove the convexity by going at a right angle in the middle of the stone to form a concavity and then going the whole length of the stone to flat.

Most of the time the stone will be concave so this step isn't needed.

"We do use Arkansas stones in the toolroom for stoneing saws and other precise sharpening where a soft stone would ruin the geometry of what we are sharpening up."

How are soft stones more likely than hard stones to ruin (alter?) the object being sharpened?

I do, however, use a diamond plate for flattening both water and oilstones(I use soapwater)and have received good results.

Perhaps the best thing you did for me was suggesting the lilywhite. For me, it has fast cutting like a waterstone and flattens easily. It is the last stage before I go to 5K and 8K shaptons. Now, though, I will have to check out your superstones.Regards, Mike

So my question is, what should one use to flatten a 220 grit waterstone? Since the wear quickly, they need flattening a lot.