|

|

05/17/2011 |

About every week or so another design for a "sharpening station" gets published. I get it. Sharpening is a lot messier than working wood and everyone want to contain the mess. Living in an apartment I have never had the luxury of space where I could build a free standing sharpening station. So over the years I have used the following, very convenient, every easy to implement, solutions. About every week or so another design for a "sharpening station" gets published. I get it. Sharpening is a lot messier than working wood and everyone want to contain the mess. Living in an apartment I have never had the luxury of space where I could build a free standing sharpening station. So over the years I have used the following, very convenient, every easy to implement, solutions.

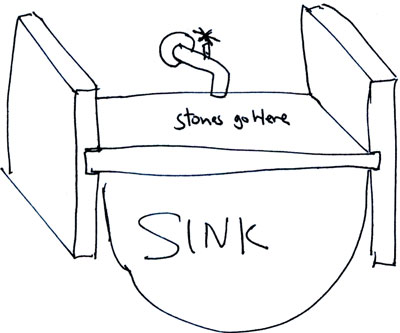

1) The bathroom sink "H". I don't have this any more (hence the sketch) but until I moved my workshop to the showroom I never had a place to leave stuff so I would sharpen my tools in the evening at home when I couldn't do any other shop stuff. All it is is an "H" that fits fairly snugly over the bathroom sink. You can drill a hole in it for drainage but you don't have to. And I originally was worried if it needed a wedge or something to snug it again the sink keep it from moving around as I sharpen. It was a snug fit as is and worked fine. I used it for fifteen years or so. This keeps the waterstone mess in the bathroom. The sink is at the right height. It was rock solid and worked great. 1) The bathroom sink "H". I don't have this any more (hence the sketch) but until I moved my workshop to the showroom I never had a place to leave stuff so I would sharpen my tools in the evening at home when I couldn't do any other shop stuff. All it is is an "H" that fits fairly snugly over the bathroom sink. You can drill a hole in it for drainage but you don't have to. And I originally was worried if it needed a wedge or something to snug it again the sink keep it from moving around as I sharpen. It was a snug fit as is and worked fine. I used it for fifteen years or so. This keeps the waterstone mess in the bathroom. The sink is at the right height. It was rock solid and worked great.

2) Once I moved to my current apartment, the "H" for the old sink didn't fit the new sink, and anyway I moved sharpening to the showroom shop and never got around to making a new "H". The only thing I sharpen at home now are kitchen knives which I do in the kitchen. I have a metal sink bridge, which I like but I find myself most of the time just putting the stone on the kitchen counter. A wet paper towel underneath the stone keeps it from scratching the counter-top and most important prevents the stone from slipping around. It really really works well and is much more convenient than all the holders that I have used for preventing slippage. 2) Once I moved to my current apartment, the "H" for the old sink didn't fit the new sink, and anyway I moved sharpening to the showroom shop and never got around to making a new "H". The only thing I sharpen at home now are kitchen knives which I do in the kitchen. I have a metal sink bridge, which I like but I find myself most of the time just putting the stone on the kitchen counter. A wet paper towel underneath the stone keeps it from scratching the counter-top and most important prevents the stone from slipping around. It really really works well and is much more convenient than all the holders that I have used for preventing slippage.

5) In the workshop I wanted to protect my workbench from the mess of sharpening so I took a piece of plywood and screwed a stop underneath it so that I can clamp it in my face vice. I never found the need for a rim to keep water from overflowing, and over the years the plywood has been impregnated with layer upon layer of waterstone residue (which doesn't seem to bother anyone). I made one big mistake. I should have made it out of 1/2" instead of the 1/4" material I used - the 1/4" has warped over the years. 5) In the workshop I wanted to protect my workbench from the mess of sharpening so I took a piece of plywood and screwed a stop underneath it so that I can clamp it in my face vice. I never found the need for a rim to keep water from overflowing, and over the years the plywood has been impregnated with layer upon layer of waterstone residue (which doesn't seem to bother anyone). I made one big mistake. I should have made it out of 1/2" instead of the 1/4" material I used - the 1/4" has warped over the years.

4) Now that I have the space, this year I plan to finally set up a dedicated sharpening station. I doesn't have to be big, or fancy, 2' x 3' would be plenty but when something is dull the less time it takes to start the sharpening process the less chance I have of talking myself out of doing it. (no picture or drawing because it hasn't been drawn or built yet). I don't expect it to work better than my current piece of plywood solution but having it set up for use all the time will save me effort and the "I don't want to clean my bench before I can sharpen stuff" problem. 4) Now that I have the space, this year I plan to finally set up a dedicated sharpening station. I doesn't have to be big, or fancy, 2' x 3' would be plenty but when something is dull the less time it takes to start the sharpening process the less chance I have of talking myself out of doing it. (no picture or drawing because it hasn't been drawn or built yet). I don't expect it to work better than my current piece of plywood solution but having it set up for use all the time will save me effort and the "I don't want to clean my bench before I can sharpen stuff" problem.

|

Join the conversation |

|

Joel's Blog

Joel's Blog Built-It Blog

Built-It Blog Video Roundup

Video Roundup Classes & Events

Classes & Events Work Magazine

Work Magazine