|

|

03/18/2010 |

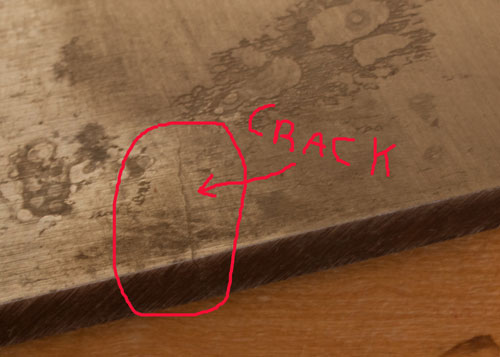

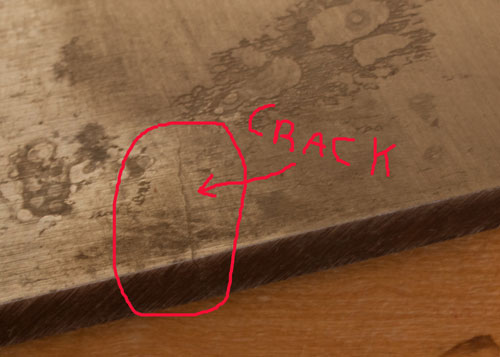

In my last blog entry I mentioned that a plane I was sharpening up had a cracked iron (see above) but I didn't think it would matter. Well it does :(. In my last blog entry I mentioned that a plane I was sharpening up had a cracked iron (see above) but I didn't think it would matter. Well it does :(.

The plane (below) is a late 18th very early 19th century mitre plane with a replaced iron, a replaced (incorrect) wedge and a replaced strike button. There is a maker stamp inside on the throat (where it should be in a plane this early) but it is totally obscured, over-stamped, and so far unreadable. It might be Gabriel as the plane kind of looks like a Gabriel but that might be just wishful thinking on my part. The un-laminated iron is unmarked, shows signs of heavy rust that was removed, and as I said has a bad crack on one side that goes from the front to the back of the blade (see above).

I brought it in to the shop so I can do a comparison between bevel up and bevel down planes using average condition tools - not something special but now I have a problem. This iron was never properly sharpened - my guess is a dealer just took an unused iron he bought somewhere, ground a bevel (burned one corner of the iron too) and stuck it in. From a collector point of view - it doesn't matter as once the iron is replaced - it's replaced.

But on flattening the back I discovered that 1 - the steel is really really hard, much harder than it should be, and the iron is warped way past what I am willing to lap out by hand. I mean really warped - twisting the night away warped. Which of course explains the crack. What happened was that the iron was improperly heat treated, it warped and cracked on quenching and the maker just put it aside and never finished it. But on flattening the back I discovered that 1 - the steel is really really hard, much harder than it should be, and the iron is warped way past what I am willing to lap out by hand. I mean really warped - twisting the night away warped. Which of course explains the crack. What happened was that the iron was improperly heat treated, it warped and cracked on quenching and the maker just put it aside and never finished it.

I'm not actually annoyed at the dealer but it does put my project back a little while I poke around for another iron. Also as a wedged plane it need a tapered iron - and this replacement is parallel - so I want to fix that too while I am at it. If I really get up a head of steam I will replace the wedge too - but I'm not optimistic that I will get up the necessary steam as the current wedge does work - (but will need to be fitted for the new iron in any case).

|

Join the conversation |

|

Joel's Blog

Joel's Blog Built-It Blog

Built-It Blog Video Roundup

Video Roundup Classes & Events

Classes & Events Work Magazine

Work Magazine

In my last

In my last  But on flattening the back I discovered that 1 - the steel is really really hard, much harder than it should be, and the iron is warped way past what I am willing to lap out by hand. I mean really warped - twisting the night away warped. Which of course explains the crack. What happened was that the iron was improperly heat treated, it warped and cracked on quenching and the maker just put it aside and never finished it.

But on flattening the back I discovered that 1 - the steel is really really hard, much harder than it should be, and the iron is warped way past what I am willing to lap out by hand. I mean really warped - twisting the night away warped. Which of course explains the crack. What happened was that the iron was improperly heat treated, it warped and cracked on quenching and the maker just put it aside and never finished it.

Much easier than trying to find an old iron that is a half-way fit. At least that's what I do. I can't afford to buy infills that are "all there", but I've lucked into a couple that friends were going to throw away because they had no irons. No miters for free yet, but one can always dream!

Is it because with a tapered iron you should never have to strike the body being able to loosen & tighten by tapping the iron or wedge? Are their other reasons?

Thanks

Get one of those laminated blades from Chris Sholz and grind down the soft side to the proper taper.

Stephen