|

|

|

Joel's Blog Joel's Blog |

Built-It Blog Built-It Blog |

Video Roundup Video Roundup |

Classes & Events Classes & Events |

Work Magazine Work Magazine |

|

Hours: M-F 9:00-5:00, closed Sat,Sun Our Guarantee & Return Policy Shipping and Sales Tax Info Privacy Policy Holiday Calendar |

|

Contact Us:

Email: support@toolsforworkingwood.com Phone: 800-426-4613 or 718-499-5877 Visit Us in Brooklyn: Directions to Our Showroom © 1999-2019 toolsforworkingwood.com Powered by 01 Inc. Coded entirely in NYC |

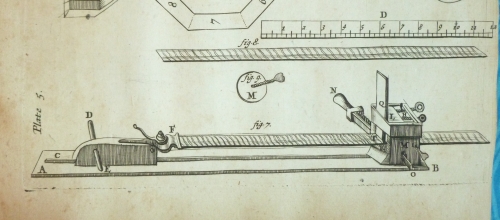

During my last visit to the

During my last visit to the  met. You can see the

met. You can see the  It makes sense that Moxon who began his carrier in Holland was familiar with the machine because the machine originated in Holland.

It makes sense that Moxon who began his carrier in Holland was familiar with the machine because the machine originated in Holland.  and you get a wavy molding. Scratch beading works perfectly in brittle dense materials like ebony and ivory that you find in high end work.

and you get a wavy molding. Scratch beading works perfectly in brittle dense materials like ebony and ivory that you find in high end work.

I've wanted to rebuild the chest to some extent at least, but wasn't sure about the molding. Now I have an idea how to do it.

So when is Tools for Working Wood going to offer one of these wavy machines?

Stephen

I've got to make one! 2014 is looking pretty clear.